Several inter-related varietal, orchard and management factors influence the incidence of scald.

Scald incidence (cont from last issue)

Several inter-related varietal, orchard and management factors influence the incidence of scald, including tree vigour and nutrition, preharvest temperatures, sunlight, rainfall, fruit size and mineral content.

However, the major factors influencing scald susceptibility are:

fruit maturity: immature fruit are more susceptible than mature fruit

seasonal conditions: fruit grown in warm, dry areas is more susceptible to scald than fruit grown in cool moist climates

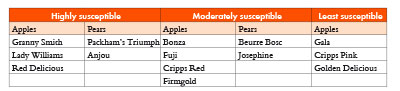

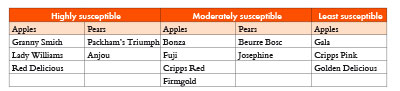

variety: fruit variety is probably the overriding factor in scald development.

Scald severity

Factors affecting scald severity include:

• storage atmosphere composition and ventilation

• storage temperature and duration.

Scald control

Scald can be controlled by postharvest chemical treatments such as:

• diphenylamine (DPA) or

• 1-methylcyclopropane (1-MCP) or

• dynamically controlled atmospheres (DCA).

Diphenylamine treatment

Scald can be controlled with diphenylamine (DPA) as a postharvest dip, drench or by fogging. However, DPA should not be used on export fruit unless permitted by the importing country.

DPA application rates depend on variety, district and the composition of the storage atmosphere. Therefore, application rates need to be adjusted according to the variety being treated, not only to control scald but to avoid damage to the skin.

DPA must be used according to label instructions; residue issues have occurred from not following label rates, inadequate mixing of the dip tanks and incorrect top-up procedures. The postharvest dipping manual Guidelines for Postharvest Drenching of Apples and Pears provides further information.

DPA application

DPA can be applied via dip/drench or fogging.

As a dip/drench, DPA should be applied as soon as possible after harvest; delaying treatment by two weeks or more greatly reduces its effectiveness.

Using a fogging system to apply DPA is a relatively new and efficient method. It involves using a special liquid form of DPA that is suitable for use with a thermal electro-fogger to form a fine fog, which is used on dry fruit.

Similar to the dip application of DPA, this treatment should be applied as soon as possible after harvest and within 15 days of harvest and storage.

Electro-foggers should only be used by qualified certified operators due to the high level of safety requirements (such as full-face respirator with organic vapour filter) for this application method.

All product label and safety precautions must be followed.

Potential issues with DPA treatment

DPA has been used for the last 60 years to successfully manage scald but some markets, particularly the EU, have no tolerance to DPA residues in fruit.

A major problem with the long and continued use of DPA in packing houses is that chemical residues can sometimes impregnate fruit bins, packing lines and storage cool rooms over time. These DPA residues can then potentially re-contaminate non-DPA treated fruit, causing potential market access issues. Therefore, alternative scald control measures should be considered.

1-methylcyclopropene treatment

1-methylcyclopropane (1-MCP) inhibits scald while maintaining apple quality during storage.

(cont next issue)

Download the Orchard plant protection guide

See this article in Tree Fruit June 2022